Torrent Group, 100 Years of Innovation

For over a century, Torrent Group has been providing closure solutions to the global olive oil (EVOO), spirits, and wine sectors. We celebrated our Centennial in 2018, grateful for the support of our clients, whom we always work closely with. This would not be possible without the unprecedented involvement of a team of professionals committed to excellence.

Torrent Group’s journey is marked by a constant pursuit of innovation and excellence in developing “Ad Hoc” closure solutions. In fact, we are the world’s first manufacturer of non-refillable caps for EVOO and the second for spirits and liquors. From cork bottle tops to non-refillable closures, Torrent Group has been a pioneer.

Torrent Group, from Cork Bottle Tops to Non-Refillable Closures

Our journey began over a hundred years ago with cork caps, evolving from cylindrical and conical shapes to an innovative alternative: the ‘cabezudos’ closures.

Even then, we provided the first protective and safety measures to the food industry by treating the stopper with paraffin and hot-melt adhesive. In the following years, we developed incredible cork stopper decoration techniques, creating a distinguishing factor.

In the 1970s, Torrent Group again enhanced our offerings, introducing new product alternatives to customers. This time, aluminum was chosen to renew closure solutions. We led a complete revolution, bringing about a positive change in the non-refillable stopper sector. We incorporated and developed all the necessary technology to offer our customers the aluminum screw cap.

Torrent Group: Non-Refillable Closures

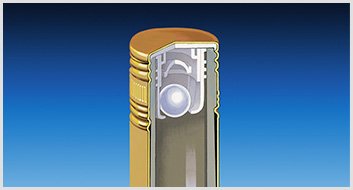

At that time, we developed the first non-refillable valve, which, when combined with the aluminum cap, offered the highest anti-counterfeiting security in the market.

In the last two decades of the twentieth century, Torrent technologically modernized and developed new models, obtaining various patents that made an impact worldwide.

Torrent Group: R&D&I

With this commitment to Research, Development, and Innovation (R&D&I), Torrent Group entered the twenty-first century. These three pillars have been key to becoming a leading company in the closure sector.

Over the past decade, international expansion has been significant, with the opening of factories in India and Africa. New distribution channels were established in Mexico, Russia, and Colombia, in addition to the more than 25 existing ones.

A Century-long Journey with Torrent Group:

First natural cork conical caps.

Introduction of the bulbous cork stopper model: a cork that can be opened by hand without a corkscrew.

Introduction of the bulbous cork bottle tops with wooden crowns to the market.

Development of new materials for the bulbous closures. A marriage of cork and plastic.

For the first time, custom-designed plastic crowns for the bulbous bottle tops hit the market, a real game-changer.

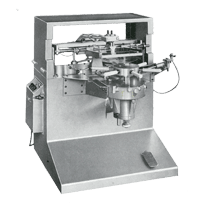

Introduction of the first injection machines.

We were the pioneers in using hot glue for bonding cork, tackling the taste and smell issues posed by the previously used adhesives.

Setting new food safety standards by introducing paraffin to isolate impurities and ease the sealing process.

Launch of the first short pilfer-proof aluminum cap.

Research, patenting, and launch of the internal tamper-proof cap. Expanding the range with the release of the long-threaded aluminum cap.

Introduction of the first side-decorating equipment.

Launch of the extra-long threaded aluminum cap.

Development, patenting, and release of the first 100% plastic internal tamper-proof cap.

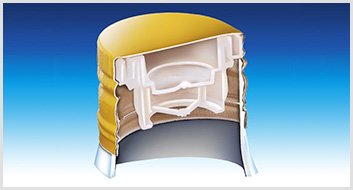

Design, development, and launch of the drip-reducing spout cap for olive oil.

Development, patenting, and launch of the first 100% plastic internal tamper-proof cap.

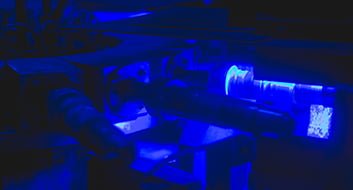

Incorporation of machine vision in production equipment for quality control.

Introduction of ultraviolet light ink-drying technology.

First company to apply hot-foil decorating technique on aluminum capsules.

Patent development and launch of the Captor model, innovating in safety and improving the aesthetics of tamper-proof caps.

Implementation of more ecological and efficient production processes, introduction of the Eco Machine.

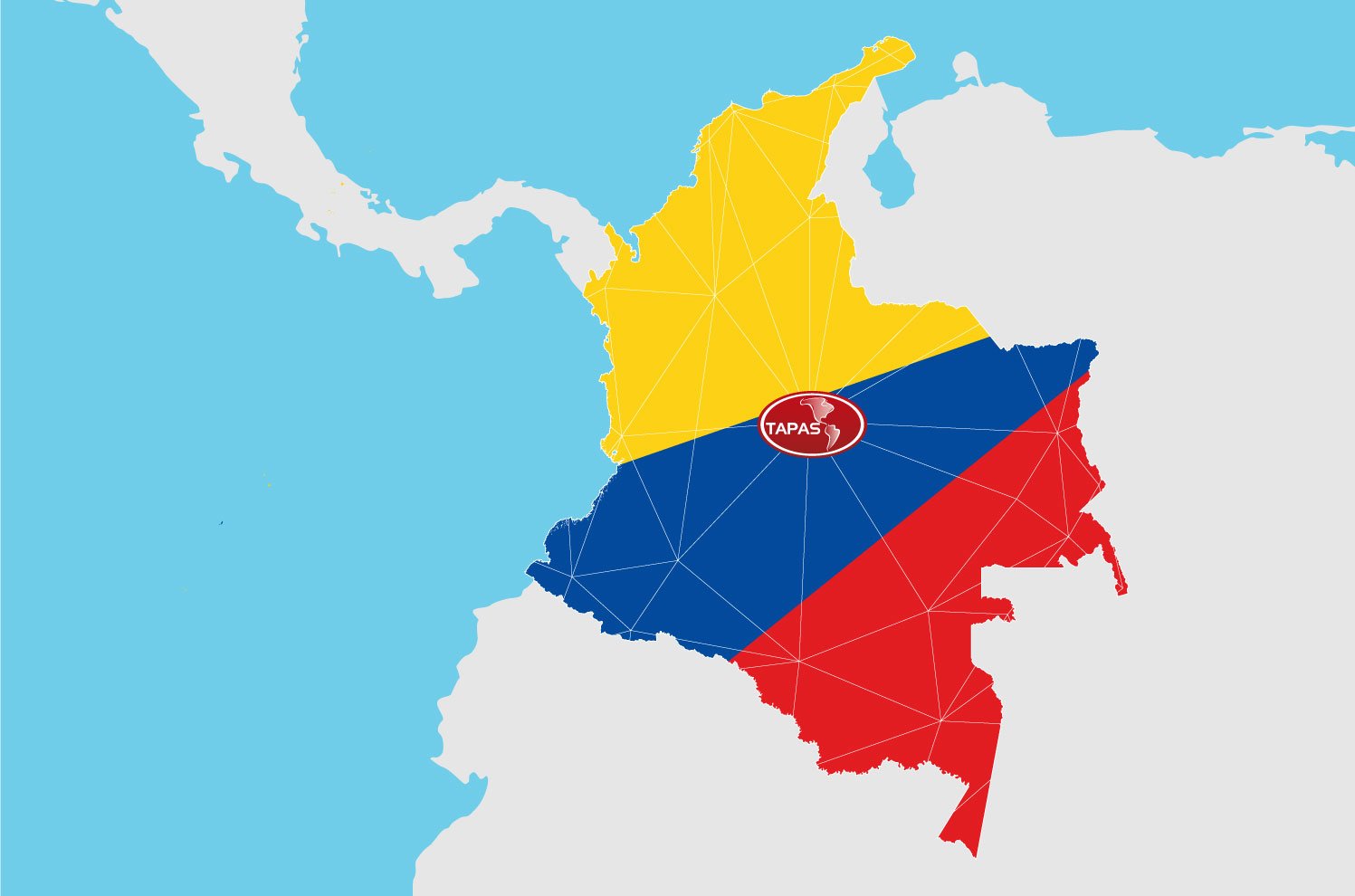

Launch of Tapas de las Américas (TDA), our headquarters in Colombia.

Development, patenting, and launch of the V90 model with a telescopic drip-reducing spout.

Opening of Torrent Russia.

Development, patenting, and launch of the Sintra model. Innovation and high protection for markets at high risk of fraud or counterfeit, offering a new opening experience.

Inauguration of the new Lithography Plant (Metalgráfica). Development, patenting, and launch of the NipTop model. A new opening experience for cost-effective and easily applied caps.

Start of the production plant in India, Alisha Torrent Closures (ATC).

Launch of the Torrent distributor in Mexico.

Opening of the R&D center, Torrent Innova.

Expansion and relocation of the production plant in India (ATC).

Inauguration of the new Grupo Torrent factory in Kenya (TEAL).

Acquisition of Heirs of Torrent Miranda.

Celebration of Grupo Torrent’s Centennial.

Inauguration of the new sales department offices in Spain.

The Distributor in the United Kingdom begins its activity.

The Torrent Mold project sees the light, brought to you by Torrent Innova.

Installation of photovoltaic panels in all production plants in Spain.

Torrent Capsule Expansion.

Opening of the model workshop.